About our farm

Creative thinking and strong will with the help of the great efforts of Pars Farasoo Jam human forces, in addition to the fact that an unused and barren land has become a huge and effective production and industrial unit in Qazvin province, we have been able to use modern world knowledge, implemented the most modern livestock methods in the country and according to the officials and monitoring devices, we are at the highest quality level of standards.

This company has stablished at 2009 with purchasing of 500 pregnant young cows. A total of 1,200 milky cows are now being milked at three times per a day.

Raw Milk

Raw milk as the most important product of Farasoo Jam Pars Industrial Livestock, with a high sensitivity of the experts and the forces of this production set , and with the best quality possible to sales associates and customers.

heifer

Bull

The Bull needs continuous monitoring due to the smallness of the herd and its importance to increase the number of livestock in the coming few years on the one hand and the necessity of maintaining health and increasing weight to enter the killing phase on the other .

Flushing

Technical knowledge

Healthy Life

Healthy milk

Healthy livestock

Get to know us better

Our program for animal health and the products you want can be summarized in several sections

mechanized collection of fertilizer in Flushing method

This system has been implemented for the first time in the country and the Middle East at the same time. The accumulation of fertilizers in the passage of livestock is carried out through an intense flow of water. It is managed with a slope of 1.5 % , and then the water is again used in the system after the separation of the dry material from the fertilizer water. It is possible to use fertilizer in cultivation and gardening.

feeding unit

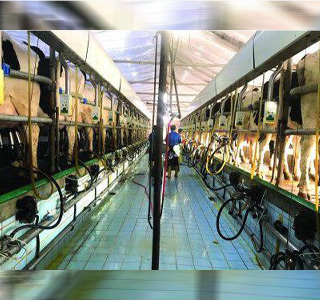

fully mechanized Milking

The unit is under the full supervision of the Iranian Veterinary Organization and has fully mechanized Milking. The milk provided by the cows is immediately reduced to 4 C by the air conditioner at 37 ° C and maintained in the right tanks to send to dairy units. the benefits of this unit are a continuous supply of good quality milk. The unit production of this unit is, in a way, it has the lowest ductility, high fat at 3.5 % and high protein above 3 %.